Autonomous Trucks, Driver Retention, and the Neon Shortage

This edition covers tyre changes in autonomous trucks, less optimal truck driver retention strategies and the neon shortage that isn't behind the semiconductor shortage

Future Trucking & Logistics: From Expectations to Reality

Trucks are a critical component of modern supply chains. In Europe, 76% of freight by weight was transported by road in 2019 and in the U.S. the modal split is 79% in favor of road transport. Prior to 2021, road transport was typically the most expensive part of international transport despite usually being the shortest. It’s no surprise that a great deal of effort is now going into improving the sector’s efficiency. As truck driver shortages persist and even accentuate, automation is increasingly hailed as a potential solution. However, automation raises some interesting challenges.

Who Fix Flat Tyre in an Autonomous Truck?

Autonomous trucks have the potential to improve road safety and transport efficiency. While driving takes up most of a truck driver’s time, it isn’t the only task a driver must perform during a workday. This recent article points out just that: drivers do much more than just driving, including changing blown out tyres. Removing the driver from the seat requires finding new ways to deal with exceptional situations.

There are three components to the autonomous truck flat tyre problem: identifying tyre failure, preventing or predicting a blowout, and replacing the tyre. Sensors and algorithms are quite effective at picking up deviations from normal operations (i.e. tyre failure) and raising an alert. Similarly, technology tools are reasonably effective at extracting use patterns from historical data and issuing predictions for future tyre failure. However, identifying tyre failure and predicting future failure both rely on the designers’ understanding of the jobs they are automating. And that’s exactly what is generally missing in most cases. Technology is made by designers or programmers and the assumptions, knowledge, and biases are embedded in the tools they create.

Changing autonomous trucks’ tyres is premised on several assumptions worth exploring. An autonomous truck can’t change its own tyres hence it relies on signalling for assistance. This assumes that the machine is continuously connected to a data network. Whether the network is online, has sufficient capacity and coverage, are all assumptions that may or may not hold true in the real world. A tyre blowout can be resolved by an operator in 15-20 minutes. Addressing a tyre blowout in an autonomous truck will likely take hours - service crews must be called, arrive onsite and perform the tyre replacement. In the meantime, the autonomous truck is left stranded and unattended on the side of a road. How long until some ‘entrepreneurs’ like the ones on Los Angeles trains decide to exploit this opportunity?

This question does highlight a broader problem. Jobs are made up of a collection of tasks. Some tasks are recurring, some are not, and the order in which they are performed must be adapted to the operational context. When trying to automate a task that is part of a job, we tend to ignore the interconnection with other tasks that make up the job. Hence, the result, while achieving the objective of improving the efficiency and effectiveness of the task, may in fact make the job as a whole less effective or efficient. Until now, this segmented approach to automation may well be one of the reasons why autonomous trucks are not more widespread.

Tackling Truck Driver Shortages…With a Catch

Automation is yet to provide the lifeline to the trucking industry in the coming years. Until that time comes, trucking needs to tackle its existing driver shortages. I’ve written extensively about truck driver shortages in previous substacks and reports. Driver shortages are an issue virtually everywhere in the world, and the U.S. is certainly no stranger to this issue. When several trucking companies started offering training courses to bring drivers into the sector, this sounded like a step in the right direction. The catch?

Prospective drivers are locked-in contracts that prevent them from leaving the company for a year or so under the threat of legal action against themselves and their prospective employers, while at the same time being paid less than minimum wage. In effect, these contracts lock-in drivers into indentured servitude (If you’re unfamiliar with the term, indentured servitude is work without pay, the modern equivalent of slavery, with a less negative connotation).

You may be asking yourself why any company would engage in such practices. Driver turnover is absolutely massive in the U.S., up to 91% in 2019. Hence, trucking companies are simply trying to safeguard their driver training expenses. Yet, by offering such lock-in contracts with low pay, the same companies are helping perpetuate the issue further. The core issues in trucking remain unsolved: the low pay, long and irregular working hours, lack of adequate facilities and loneliness. Using lock-in contracts to solve driver retention has the same effect as using a hammer to nail a flower.

Neon and the Semiconductor Shortage

If you’ve tried to buy a new car lately, you’ve probably seen the ridiculous delivery lead-times auto retailers are quoting. The entire automotive sector works on just-in-time principles except when it comes to delivering the vehicles. The semiconductor shortage continues to play a major role in delaying production and the delivery of new vehicles. After more than two years since the semiconductor shortage started, a new setback seems to have appeared: neon shortages due to the Russo-Ukrainian conflict. The main issue: 70% of the world’s neon is produced in the Ukraine and neon is a key component in the manufacturing process of semiconductors. Since the outbreak of the conflict, neon supply has been constricted.

Neon is a by-product of large-scale steel production which is more common in Soviet-style steel mils in the Ukraine and Russia. Hence, neon production is concentrated in these two countries. Neon is a key element in excimer lasers which are used to generate light in semiconductor chip lithography (embedding patterns onto chips). The neon in these devices must be refilled regularly to keep them working well. A shortage of neon means lasers can’t operate hance semiconduct chips can’t be produced.

Funnily enough, this isn’t the first time a neon shortage happened. During the 2014-15 Russo-Ukrainian conflict, virtually the same story repeated itself. What’s changed this time? Two things:

First, since 2015 several companies have investigated and implemented ways of recapturing, purifying and reinjecting neon into laser systems thus reducing neon reliance and demand.

Second, since 2020 extreme ultraviolet lithography (EUV) has started replacing excimer lasers particularly for under 7 nanometre nodes. Neon may well continue to be an important element in production processes but not enough to bring semiconductor manufacturing to a halt.

While it is likely that some manufacturers may still use excimer lasers, it’s unlikely that the semiconductor shortage would be exacerbated by the neon shortage. The only places that will definitely feel the neon shortage pain are red light districts.

In other news

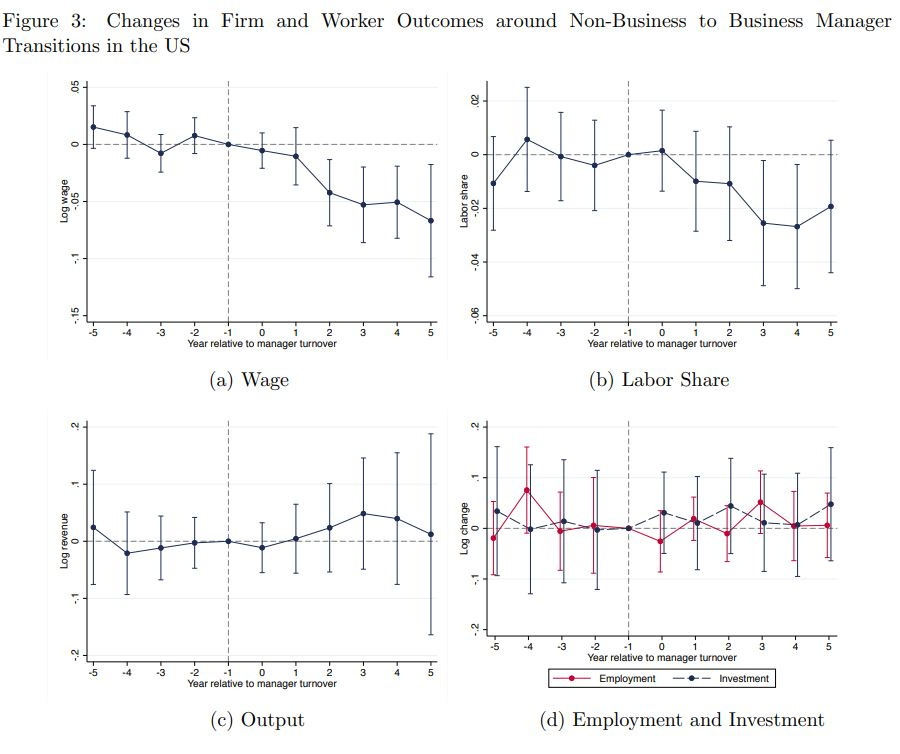

MBAs Are Great for Everyone, Except the Employees

Recent research suggests that managers with MBAs are great at reducing costs, particularly the salaries of their employees. At the same time “…evidence suggests that business managers are not more productive. Firms appointing business managers are not on differential trends and do not enjoy higher sales, productivity, investment, or employment growth following their accession.” Sounds like some MBA trained managers made it into the trucking industry as well.

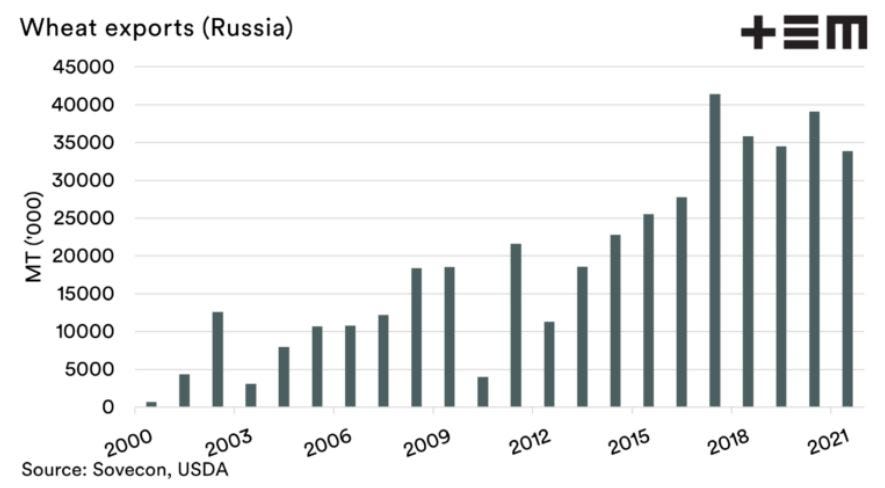

The Effect of Russian Sanctions

Despite the extensive news coverage of Russian sanctions and the skyrocketing prices for energy and food mainly in Europe, the sanctions themselves seem to have a limited effect on the Russian economy. Russia is projected to deliver just under 34 million tonnes of wheat in 2021-22 (mostly to Egypt, Turkey and Iran). And it’s not just wheat, it’s energy products too. India recently purchased 3 million barrels of Russian oil. The 30-year gas supply deal signed with China 3 weeks prior to the breakout of the conflict, added 10 billion cubic metres (bcm) of gas to previous plans of supplying 38 bcm to China. If the last two years have taught us anything, I suspect that if the first set of sanctions didn’t work, what we need is more sanctions!

Cutting Trees and Harming Wildlife to Save the Planet

In the quest to expand green energy projects, the environment is sometimes forgotten, which is funny because that’s what these projects ostensibly aim to protect. ESI Energy in the U.S. was found guilty over 150 golden and bald eagle deaths from its wind farms projects.

In Germany, the State of Hesse has issued a construction approval for a wind park which designated for destruction 2,000 hectares of forest. The most shocking bit in this story: “The massive resistance of the affected citizens was ignored by the Hesse state government, which ironically is governed by a coalition of the CDU conservatives and environmentalist Greens”. I think it’s now safe to say WTF?!